1. Negotiation

We received this customer requirement. He said that he wanted some open frame touch monitor that applied for slot machines. The entire display needed four LED strips, one on each side, two on the back.

2. Design

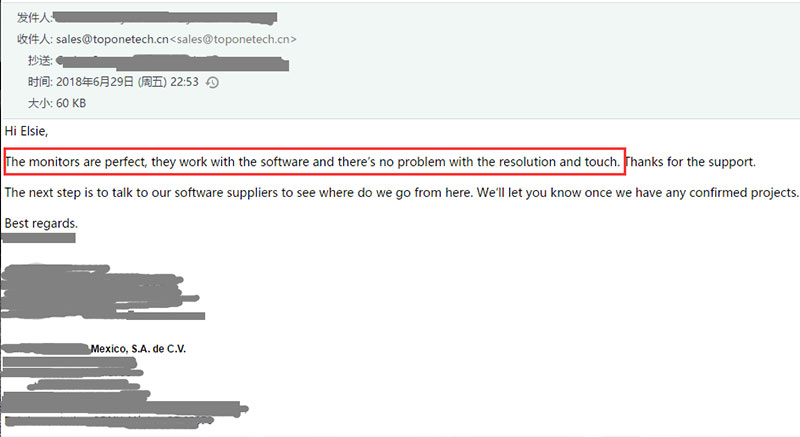

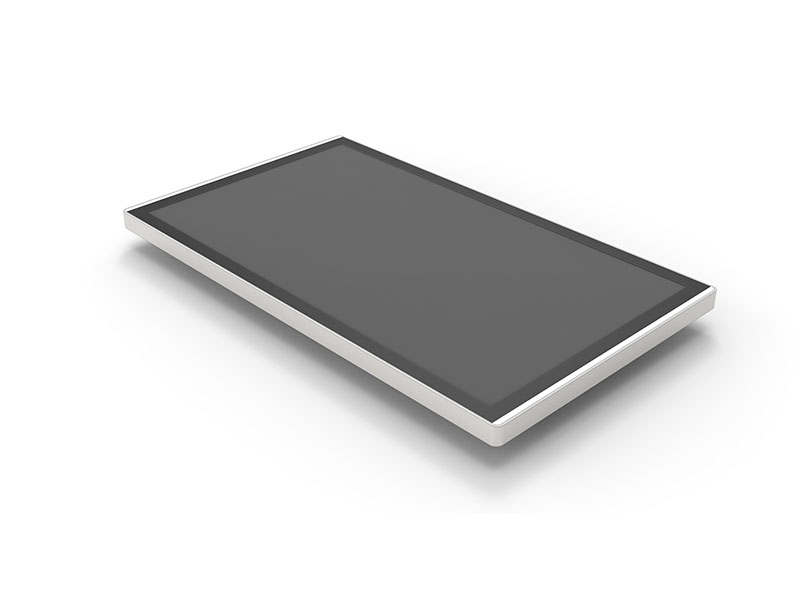

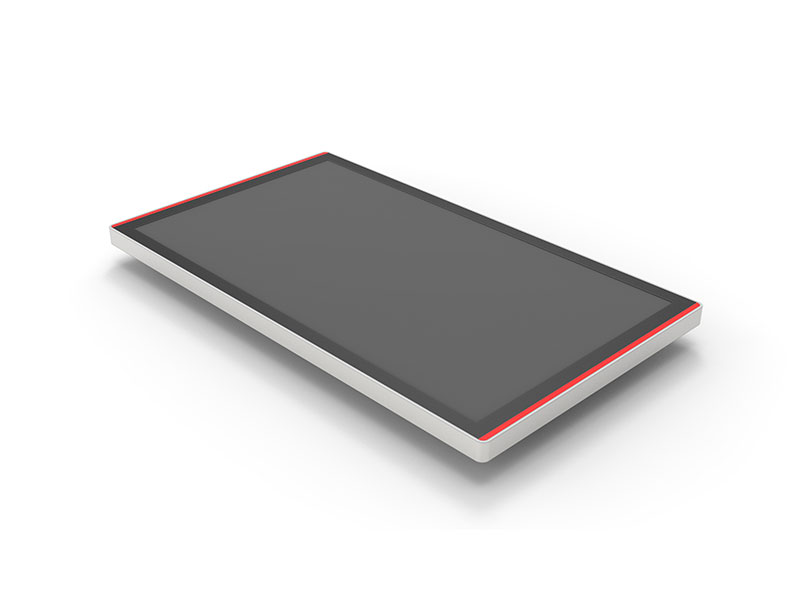

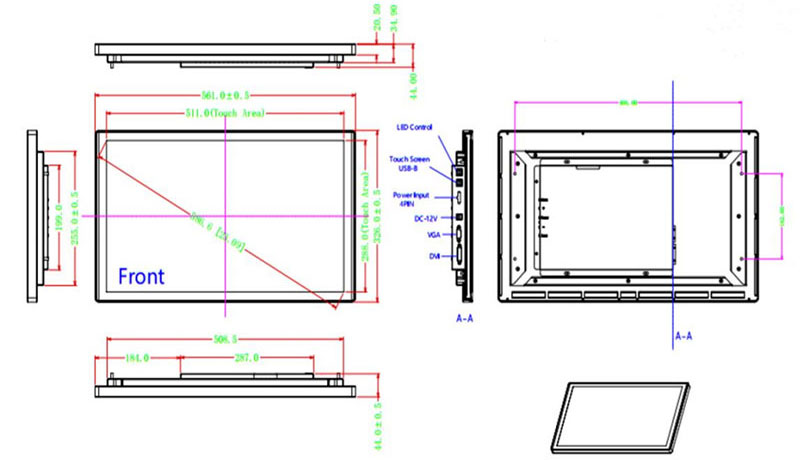

Our engineers discussed about this.Then We designed open frame touch monitor solution for him that is 23 inch, four lights all with 358 colors,and one light on each side , two lights on the back. Meanwhile, we would used the acrylic to cover the back LED light,which was to ensure the back light more beautiful and soft. For convenience,we would make all the lights controlled by remote control .

1. 3D drawing

3. Making Samples

1. Samples picture

2. Samples Video

4. Mass Production

When the customer approves the sample, we will mass manufacture for you. There is the whole process of manufacture, we are always careful to complete each step.

Touch monitors Production flow chart:Materials procurement--Incoming material inspection--Fit the touch screen and LCD screen--, Assembling the AD board-- the inverter board, and the keypad--Data line connection--Shell assembly--Finished product inspection--Aging test--external assessment--package

5. FQC

After the production is completed, we will perform a 100% inspection of the display to ensure that each product is 100% qualified.

All the products we provide must go through 9 inspection tests. Screen aging test and high and low temperature test can improve the reliability of the product effectively. And we can provide you with the best quality.

We have those test types:

1.The first one is to start the test at a temperature of 40-50°C for 24 hours, or 48 hours at normal temperature to observe whether the panel of the product is stable.

2.Temperature & Humidity Test: Usually, it will be operated at a low temperature of -10°C and a high temperature of 70°C to ensure that the product can adapt to a high-intensity working environment.

6. Shipment

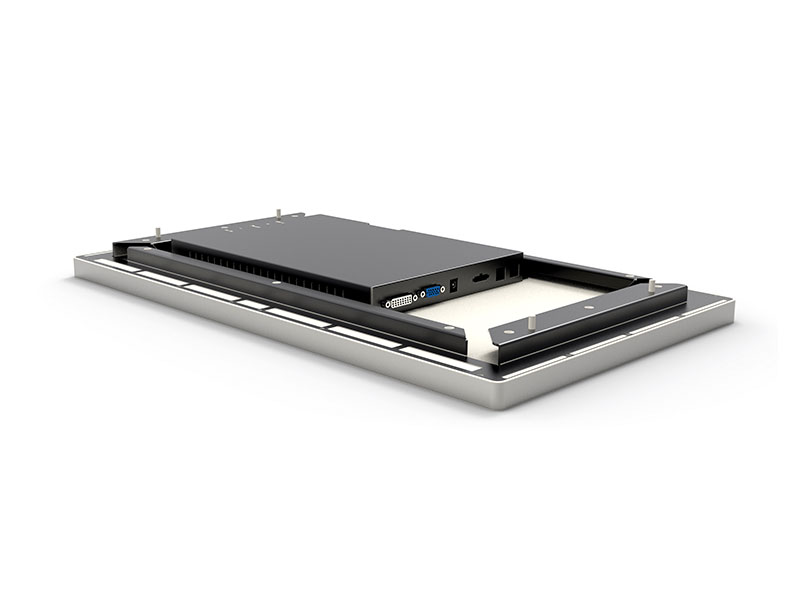

7. Customer Feedback